While possible, running iOS apps on Android comes down to one app and one paid service confirmed to work on more recent Android versions. There are some other ways too, but there’s no guarantee they’ll work on your Android device. You have to try the apps out and see what works and what doesn’t. Here’s how to run iOS apps on Android.

How Do iOS and Android Work Together?

If you’ve had a smartphone for any number of years, you’re probably aware that iOS and AndroidOS are vastly different operating systems. In fact, the two are hardly compatible at all. When we discuss running iOS apps on an Android device, we aren’t talking about downloading anything from Apple’s App Store. What we need to do is use a workaround to run iPhone apps on an Android device.

Fortunately, there are a plethora of iOS emulators available to download. These emulators let you mimic iOS on your Android device. But beware, you won’t have the full functionality of an iPhone.

Installing from Unknown Sources

Suppose you have an older Android version and manage to find a Cycada/Cider or iEMU .apk file (mentioned below) to install. In that case, you need to enable permissions that allow app installs from sources other than Google. The instructions may vary depending on the version of Android you’re running and the manufacturer of your device.

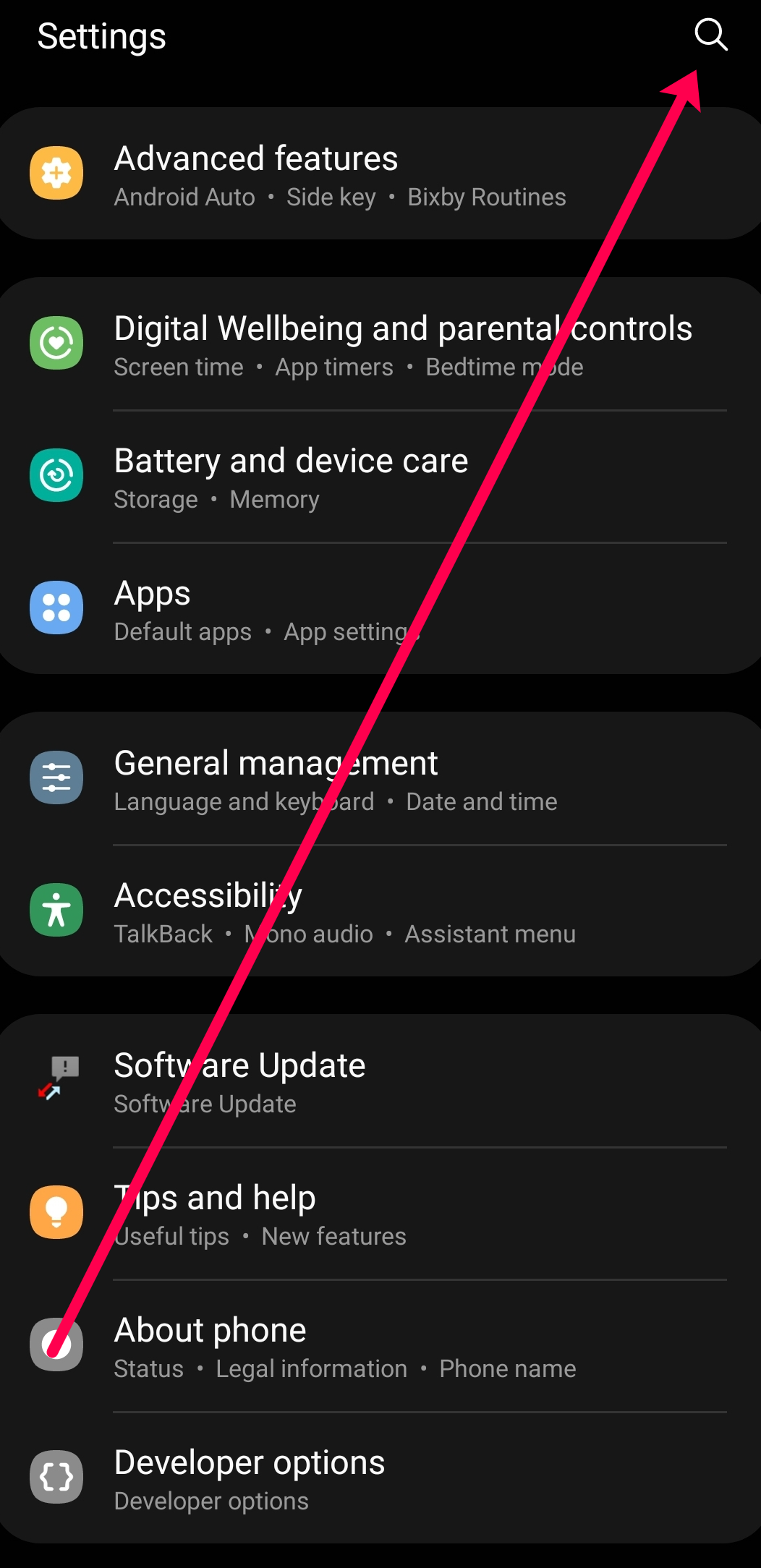

The simplest way to allow the installation of third-party apps from unknown sources is to open the Settings of your device and tap on the search icon.

Then, you can type Unknown Sources to go directly to the setting you need. But, you can also find the option by doing this:

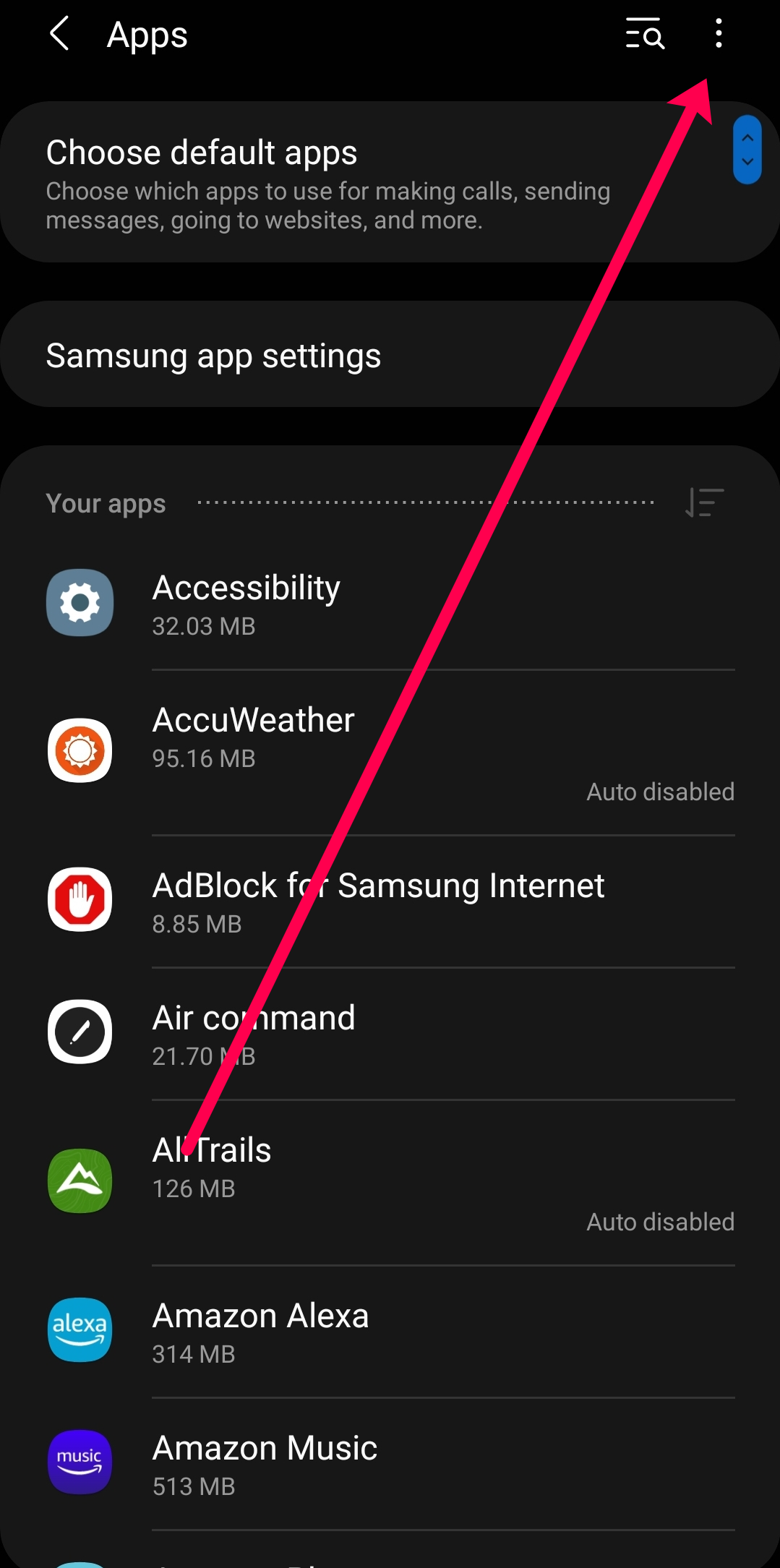

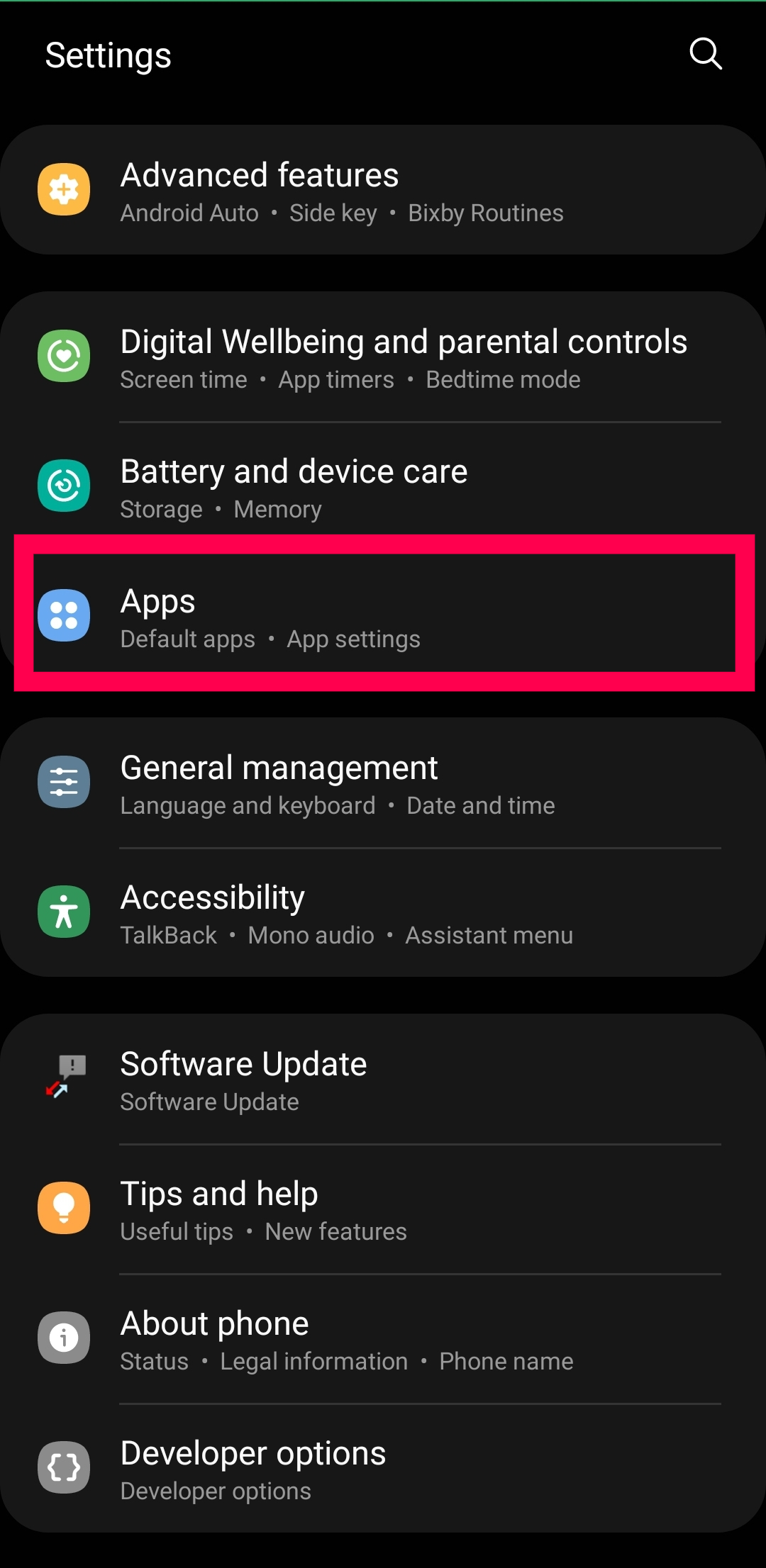

- Open Settings and tap on Apps.

- Tap on the three-dot icon in the upper right-hand corner.

- Tap on Special Access in the dropdown menu.

- Tap on Install unknown apps.

- Tap on the browser or source you’re using to install the .APK file.

- Toggle the switch next to the source to allow downloads.

After you’ve turned on the setting to allow downloads from unknown sources, you’re ready to proceed.

Common iOS Apps to Android Applications

Now it’s time for the workarounds we mentioned above. As long as you can install downloads from unknown sources, you can use the following emulators to access iOS apps on your Android device.

1. Use appetize.io in Your Android Browser to Run iOS Apps

In a sea full of iOS simulation apps, it’s interesting to see an online iOS app for Android like Appetize.io. This setup doesn’t let you install iOS apps on an Android; it simulates an iOS device using the cloud, allowing you to use iOS apps in a web browser.

Appetize.io is only accessible for the first 100 minutes, after which you need to pay to use it. Since this application is an online service, you can also use it on a PC or a Mac. Another great thing about using appetize.io on Android is that you don’t need to root your device.

2. Emulate iOS on Android using Cider

Cider is possibly the most popular iOS emulator app. It’s easy to use and completely free, also coming with no in-app purchases. This program can also help you test iOS apps, which is why it was used by iOS developers back in the day. Like other apps, Cider may not work for you if you have one of the latest Android versions, but it does otherwise work on versions 2.3 and up.

Cider lets you use nearly all of the Apple devices’ functions, not just apps, so you might want to leave at least two gigabytes of storage space free on your device. Other than that, you should have at least 512 megabytes of RAM and some additional storage space for the app itself.

3. Emulate iOS with iEMU on Your Android Device

The app iEMU (also known as Padiod) comes closest to Cider as an iOS emulator with similar capabilities. It doesn’t require you to root your Android device, but it can work on rooted ones just as well.

IEMU also has a friendly user interface, but it requires more robust hardware than Cider. It won’t work very well if you have less than a gigabyte of RAM. Also, you have to close any other apps running in the background. What also makes this emulator quite good is that it works with .zip and .ipas files.

Unfortunately, the only reputable iOS emulators for Android are Cider and iEMU. Appetize.io is an online alternative for those unwilling to install third-party apps. It is also worth noting that Cider and iEMU aren’t supported anymore. You can, however, try running iOS apps on some of these computer programs.

iPadian and Ripple are the most prominent options. iPadian is an iOS simulator, while Ripple is a Chrome extension.

Frequently Asked Questions

We’ve included the answers to more of your frequently asked questions in this section.

How do I get the full iOS experience on Android?

Unfortunately, there isn’t a way to download or install iOS on your Android device. Popular Apple applications such as Facetime and iMessage are exclusive to Apple devices so you can’t really use those on Android, even with an emulator.

Are .APK files safe to download?

.APK files are safe for the most part. But before you download anything to your Android device it’s a good idea to perform a backup to a cloud service and be leery of handing out any personal information. Your operating system is designed to protect your privacy and security. When you install or download data from an unknown source, you are bypassing a lot of security protocols.

To be safe, it’s best to only download content from trusted sources. Read reviews and investigate the source of your download before installing.

Facing the Truth about Using iOS Apps on Android

Since iOS and Android function differently, it is safe to say that there is no truly convenient way of running iOS apps on Android. Cycada/Cider and iEMU were once available but aren’t supported anymore. However, that scenario doesn’t mean that running iOS apps on Android won’t work for you. You just need to try both iOS emulators out.

You can easily try to run any iOS app on Android or run a simulator on a computer, but there’s no guarantee that they will work. On the flip side, getting even the most basic functions might be a good way to get to know iOS’s user interface better.

Disclaimer: Some pages on this site may include an affiliate link. This does not effect our editorial in any way.